Markets

Our areas of expertise

Agriculture

- Flooring

- Wall Liner

- Partitions

- Feeder Products

Value Added Capabilities

Exclusive in-house value services

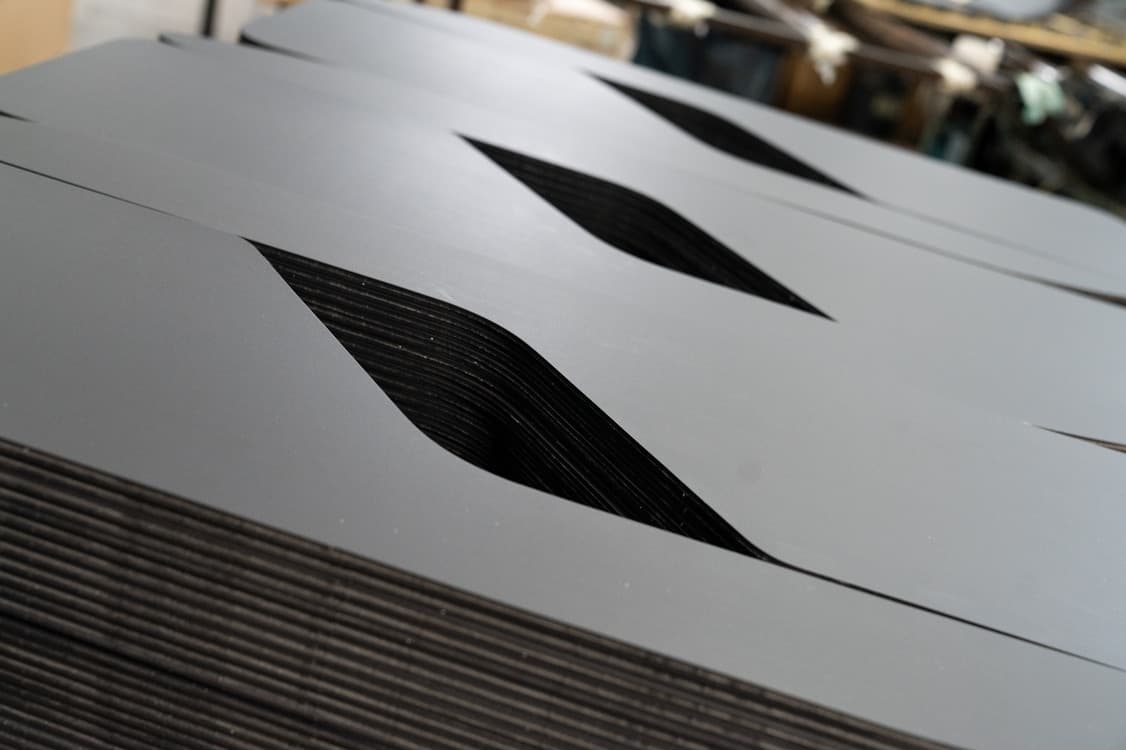

Co-Extrusion

A process that combines multiple layers of plastic materials into a single sheet, offering enhanced properties and performance for various applications.

Materials

We offer a wide range of materials for many use cases

Polyethylene

- LDPE

- MDPE

- HDPE

- HMWPE

- LLDPE

- Flame Retardant

- Talc Filled

- Utility Blends

Certifications

View our certifications

ISO 9001:2015

Certification of Registration

Contact Us

Get in Touch

Send Us a Message